INDVAL TECH’s core competence of Automotive domain plays the key role in retaining all our customers with innovative methods, processes, and latest techniques in managing the projects in the context of risk management, multiskilling the resources, quality management systems, automations for repeated activities and continuous improvement plans. This expertise is resulted in many appreciations from every customer and recommendations/references to other customers voluntarily by our customers which increased our recognition in the market with highest possible good note.

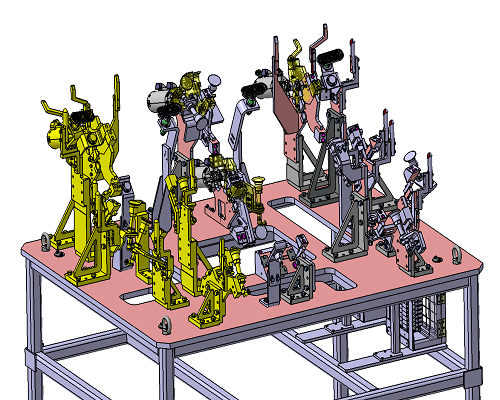

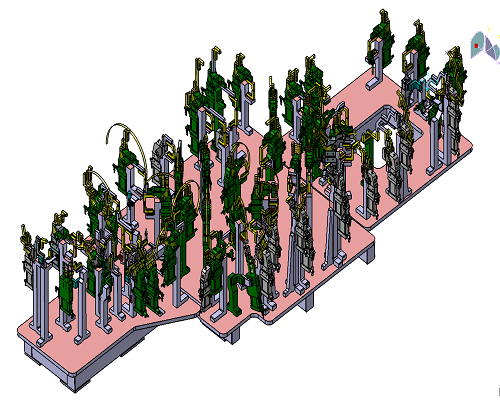

Capable to do full line BIW Fixture design projects from Pre- engineering stage to Manufacturing Drawing Release and have a considerable resource pool with familiarity with NAAMS, European, Japanese Standards with leading CAD Software’s/customer Tool Kits. Expertise related to Process Planning, Layout study Design & Simulation activities. We also design manually operated pre-production fixtures for low-volume production prototyping (low-volume production).

Our team is spearheaded by senior engineering and tooling experts with rich industrial experience of BIW welding fixture, from front to rear and from floor to the roof of a car body.

Indval technologies supplies fully automated flexible design, simulation support and supply, tailored to our customers’ requirement in an integrated ecosystem of OEM, Tier-1 & its cross functional suppliers. As a core business domain, we have established dedicated service vertical for BIW Fixture design and successfully operating since its inception and scaled up in size continuously for enhanced support for our global customers.

Mechanical Design

- Prototype tooling.

- Spot weld fixtures.

- Roller hemming fixtures.

- Arc welding fixtures

- TIG & MIG welding fixtures.

- Geo gripper stations

- Gripper docking station.

- Marriage stations.

- Conveyor Tooling.

- Main line assembly tooling.

- Turn tables

- Tooling for composite panels

Simulation

- Layout study and planning.

- Process design and validation.

- Weld study/gun selection and distribution.

- OLP generations and documentation.

- Robotic Simulation.

- Offline Programming.

- Ergonomic Study

- Line Simulation.

2D Detailing

- Manufacturing Drawings.

- Layouts.

- Bill Of Materials (BOM) independent, customized tool based or

- Flame cut drawings.

- Pneumatic Circuit diagram.

- Pay load and Buyoff sheets.

- Control sheet creation.

We will take care of BIW fixture design for

We will take care of BIW fixture design for

- All types of passenger cars

- Completely automated lines

- Semi automated lines

- Manually operated lines

- Formula 1 cars

- Composite production tooling

- Composite panel joining

- Metallic parts assemblies

- All types of commercial vehicle

- Trucks & Buses

- Cabins, Dump bodies Floors & Roofs

- Locomotive car bodies

- Underbody

- Side body

- Doors

- Roofs

- Cabins

- Luggage carriers

- Off high way vehicles

- Agricultural equipment

- Construction equipment

- Special purpose vehicles